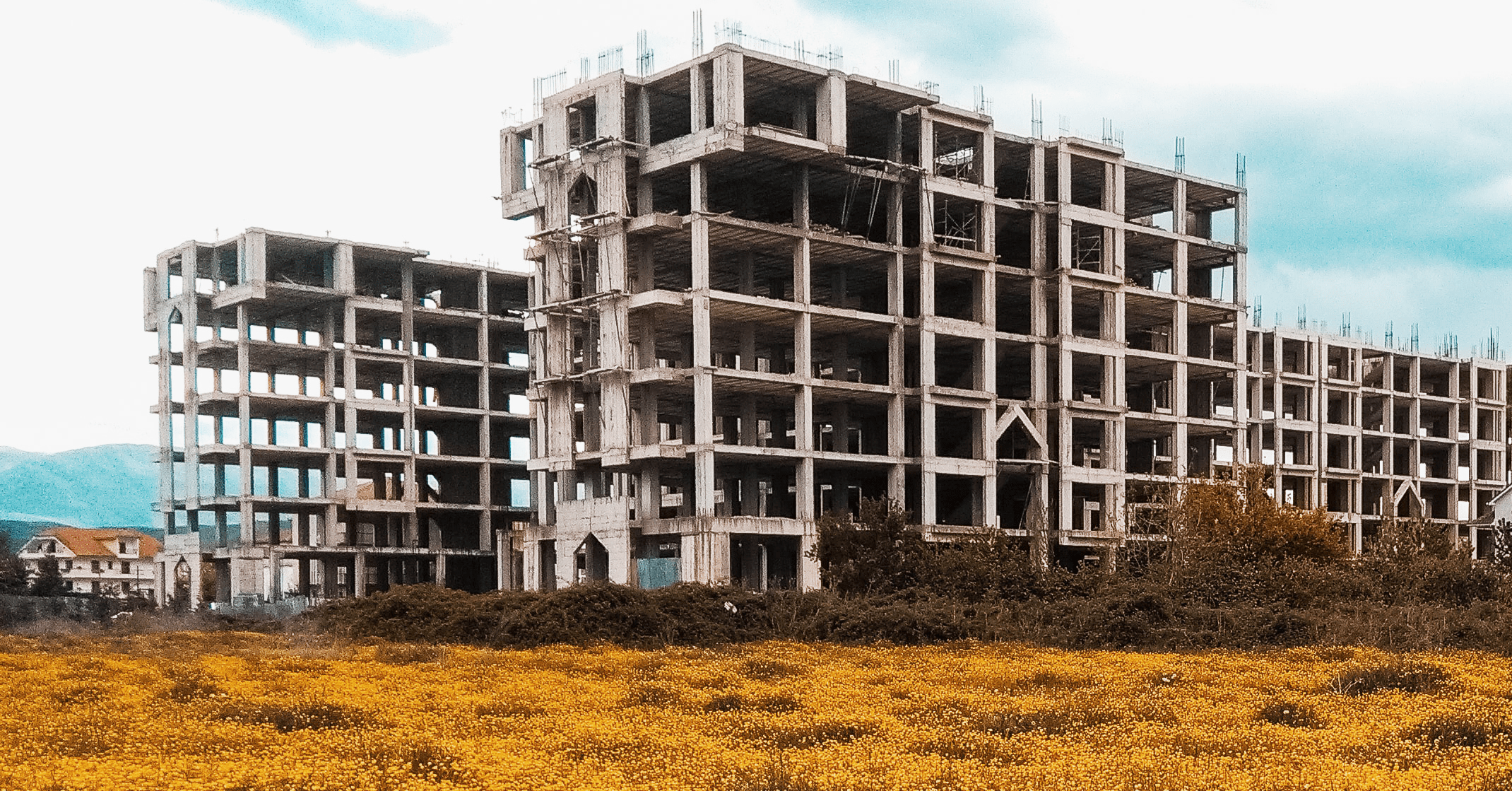

Much has already been done to make cities greener and houses more isolated and more self-sufficient, but that does not change the fact that the construction industry, is still a major climate sinner, especially when it comes to its overall CO2 emissions.

It also means that more needs to be done to reduce CO2 emissions for the benefit of the climate and for more sustainable development in the industry. A relatively easy and straightforward solution is to replace fossil fuels (diesel) with fossil-free alternatives such as B100 Biodiesel RME Premium, which is produced locally from sustainable rapeseed and which reduces CO2 emissions by up to 70% compared to ordinary diesel.

B100 Biodiesel RME can be filled in construction machinery and vehicles without the need for large investments in new equipment. The only thing it requires is that in the beginning there may be a more frequent change of fuel filter as biodiesel has a cleansing effect.

Rapeseed methyl ester for the concrete industry

In addition to the replacement or blending of the fuel itself in machines and vehicles, biodiesel in the form of rapeseed methyl ester can also be used effectively in the concrete industry, where RME can be used instead of fossil products. In this way, among other things, hydrocarbon pollution (HC) can be reduced and disposal costs reduced.

The use of RME in the concrete industry has several advantages, including:

The replacement of fossil oil with vegetable oil has in practice had positive results without significant technical difficulties

Normally, sludge and other wastes from the concrete production may contain high concentrations of hydrocarbon in traditional fossil form oil, which is eliminated by using RME

There is a huge environmental benefit that is particularly beneficial to the employees who work with the concrete, as they avoid being exposed to the harmful hydrocarbon emissions.

Oil is needed in the manufacture of concrete structures and concrete elements to ensure a high quality and a good and resistant surface treatment. It is specially used preventively, so the concrete does not burn solid and is easier to get out of the molds and production facilities.

So, if your company wants to set ambitious climate and environmental goals, then feel free to contact us to find out more about your options for the conversion to a fossil-free and sustainable operation.

"*" indicates required fields